The importance of good insulation

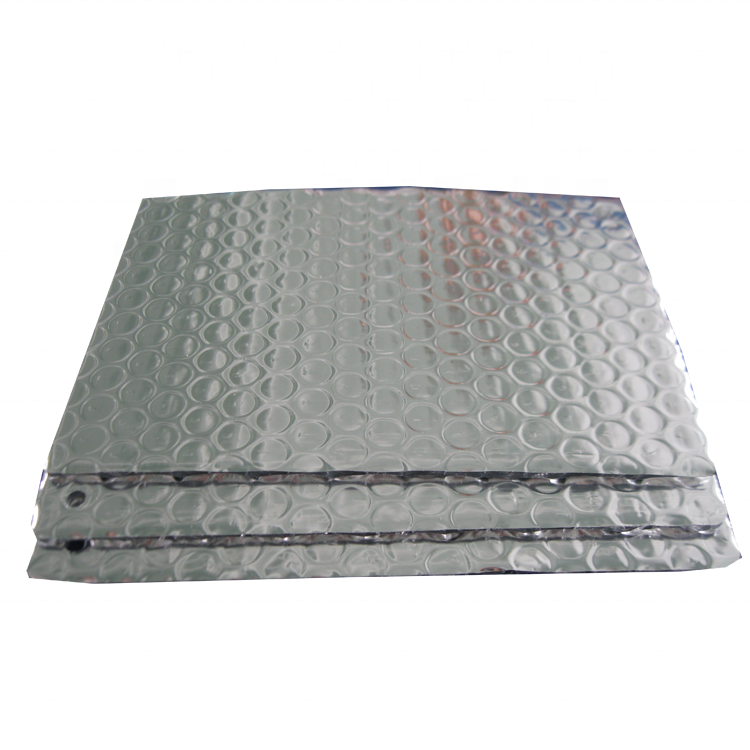

Thermal Blankets & Liners

The correct protection and conditioning of a dry cargo container generates good goods flow as well as confidence in the receivers. For this purpose, we offer our insulating coating service.

Very low costs

For a very low cost offer more quality in their journeys. Minimize the impact that your products can suffer due to temperature changes, especially in the summer and winter seasons.

General Cargo and Flexitanks

Our systems can be adapted to any type of cargo. They work with both bulk loads in Flexitank and standard shrink-wrapped loads on pallets. Their weight is only about 10kg and does not affect your payload.

Versatility on finishings

We have a wide range of finishes for any type of container. Choose whether or not to include the floor to facilitate the entry of forklifts. It allows special packagings.

Less damages

Reduce the thermal impact on the goods by 40% to 60%. Our systems offer extra protection against condensation generated during transit time as well as against odours and possible cross-contamination.